Duravit Badewanne Luv 1850x950mm Ecke re. weiß, m.nahtloser Verkleidung, 700432000000000 für 2.826,39 €

Duravit Luv Eck Badewanne rechts 185x95cm NEU in Niedersachsen - Achim | Badezimmer Ausstattung und Möbel | eBay Kleinanzeigen

Duravit Badewanne Luv 1850x950mm Ecke li. m.nahtloser Verkleidung, weiß, 700431000000000 für 2.826,39 €

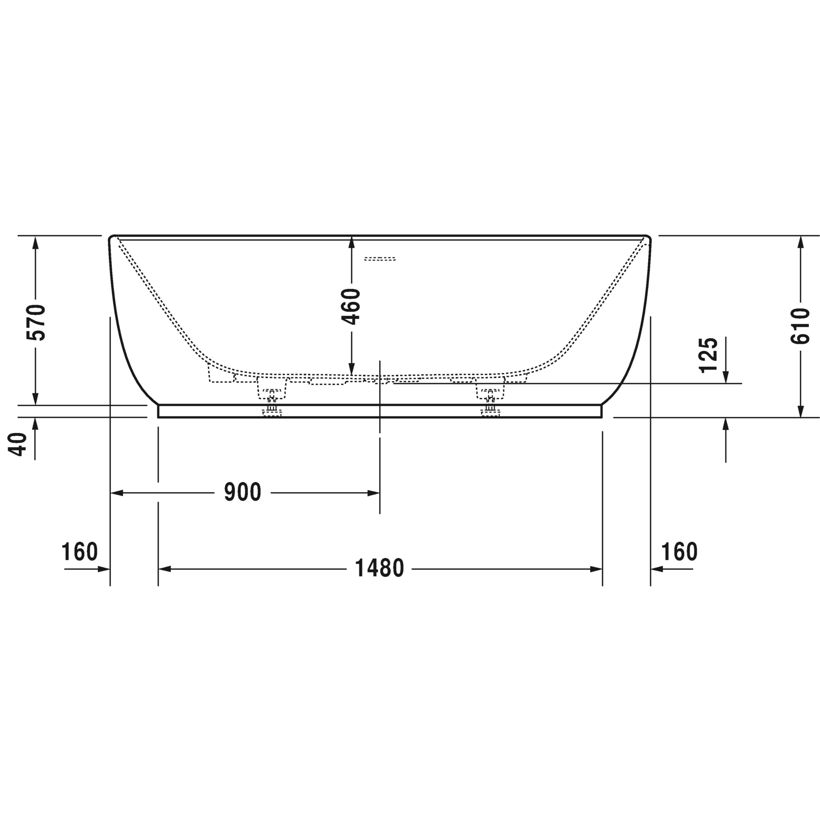

Freistehende Badewanne LUV-180 in weiss matt von DURAVIT, matte Badewanne, Badewanne Durasolid - edlesbad.ch