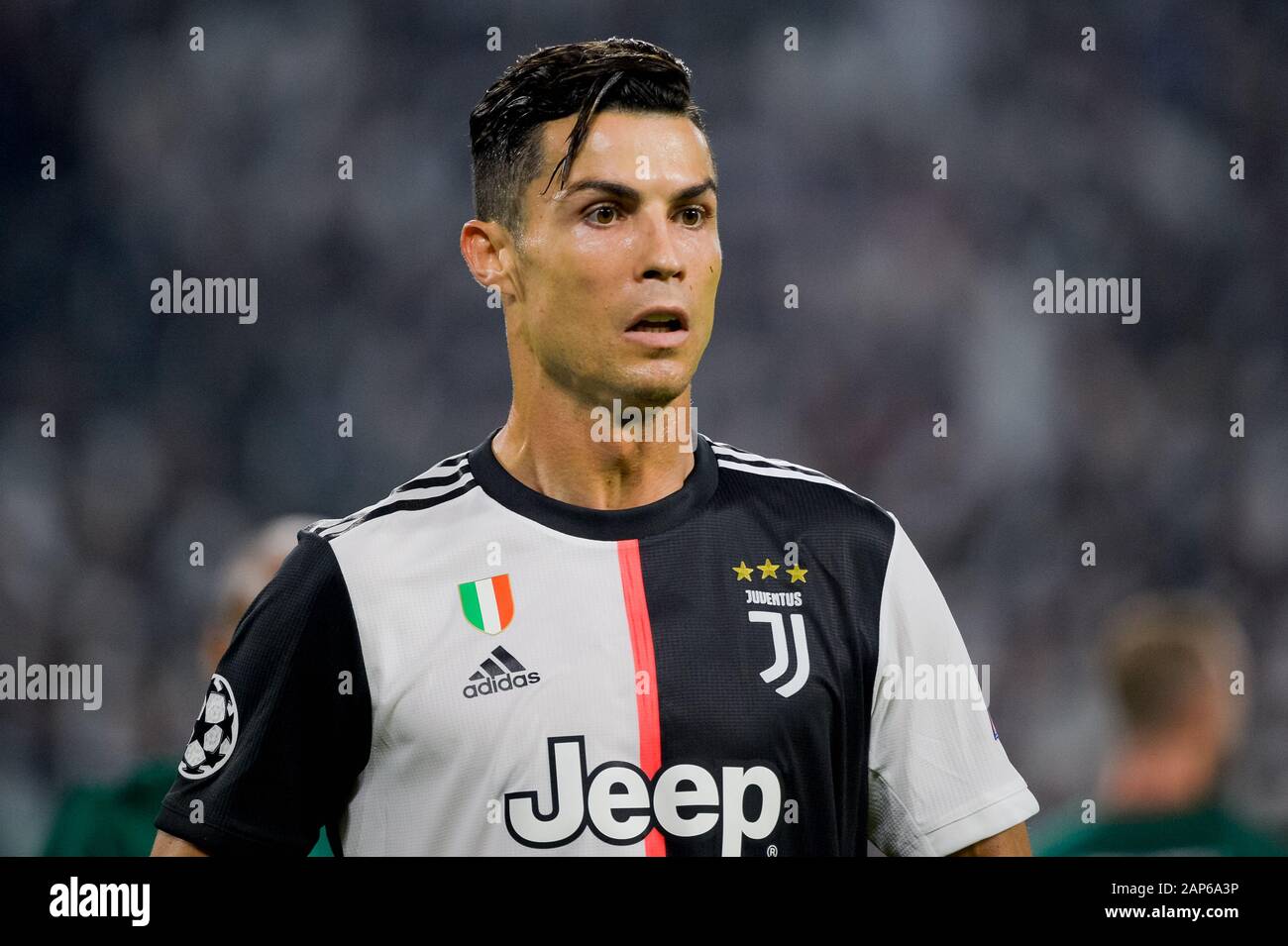

Turin - Oct 22, 2019: Cristiano Ronaldo 7 portrait. Juventus - Lokomotiv Moscow. UEFA Champions League. Mathcday 3. Allianz Stadium Stock Photo - Alamy

Serie A - Juventus: Cuadrado officially gives up his No. 7 shirt for Cristiano Ronaldo | MARCA in English

Amazon.com : Patches Juventus 2019-2020#7 Cristiano Ronaldo Home Nameset Name Set Shirt Print Font 19 20 Away : Sports & Outdoors

Cristiano Ronaldo Juventus squad number: Which shirts are available? | Football | Sport | Express.co.uk

/cdn.vox-cdn.com/uploads/chorus_asset/file/19970124/1194807218.jpg.jpg)